GRP Sectional Panel

Water Tank

GRP Sectional Panel

Water Tank

Benefits

- Benefit 1: Keeping Water Clean

- Benefit 2: Strength & Long Term Reliability

- Benefit 3: Sealing Properties And Watertightness

- Benefit 4: Complete Drainage

- Benefit 5: Thermal Insulation Property

- Benefit 6: Environmentally Friendly

- Benefit 7: Re-locability

- Benefit 8: Flexible design and Modular shape

- Benefit 9: Simplicity of Handling and Site Installation

- Benefit 10: Cost Effective Maintenance Free Solution

General Specifications

Manufacturing Process :

Hot Pressed Sheet Moulding Compound (SMC) Compression Moulding Up To 150 Degree Celsius

Tank Structural Support

- Tie-rod System

External : Hot Dipped Galvanised Steel

Internal : SS304 Tie-rod, Optional SS316*

- Roof Support

PVC pipes with GRP roof panel stiffener

*Optional: ABS pipes

- External Braced System

External : Hot Dipped Galvanised Steel

Internal : None (metal free inside)

Standard :

- Singapore Standard SS245: 2014

- Malaysia Standard MS 1390: 2010

- Similar to British Standard

- BS 7491 Part 3:1994 and BS EN 13280:2001

Materials :

Sheet Moulding Compound (SMC) consists of:

- Resin

Isophthalic unsaturated polyester resin conforming to BS 3532 specification

- Fibre Glass

Alkali free fibre glass – Type E glass

Sealant :

- Nontoxic PVC foam

- EPDM Rubber

Bolts, Nuts and Washers :

- External

Standard: Hot Dipped Galvanised Steel

*Optional: SS 304/316

- Internal

Standard : SS 304 (In-contact with water)

*Optional: SS 316 (In-contact with water)

- Roof

Standard: Hot Dipped Galvanised steel

* Optional: SS 304/316

Water Level Indicator :

- Standard: Reversed Reading

Mechanical Ball Float Type (Cat & Mouse)

- *Optional: Direct Reading Clear Tube Type

Ladder :

- External

Standard: Hot Dipped Galvanised Steel, 300mm width

- Internal

Standard: PVC or Aluminium, 300mm width

*Optional: GRP or SS 304/316, 300mm width

Sealant :

- Pipe nozzles flange not inclusive

- Flat panels will be provided upon request

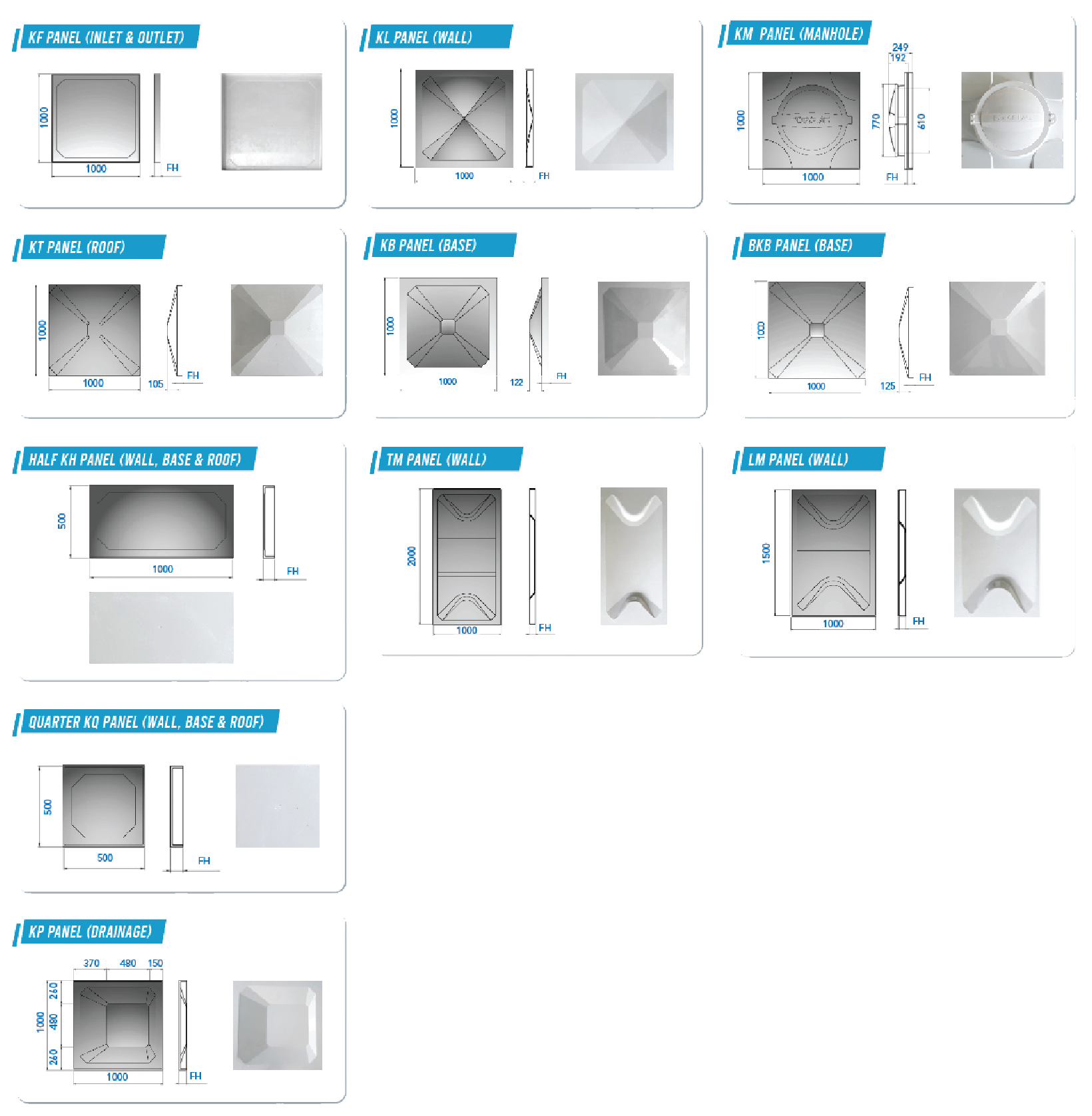

GRP Panel Design

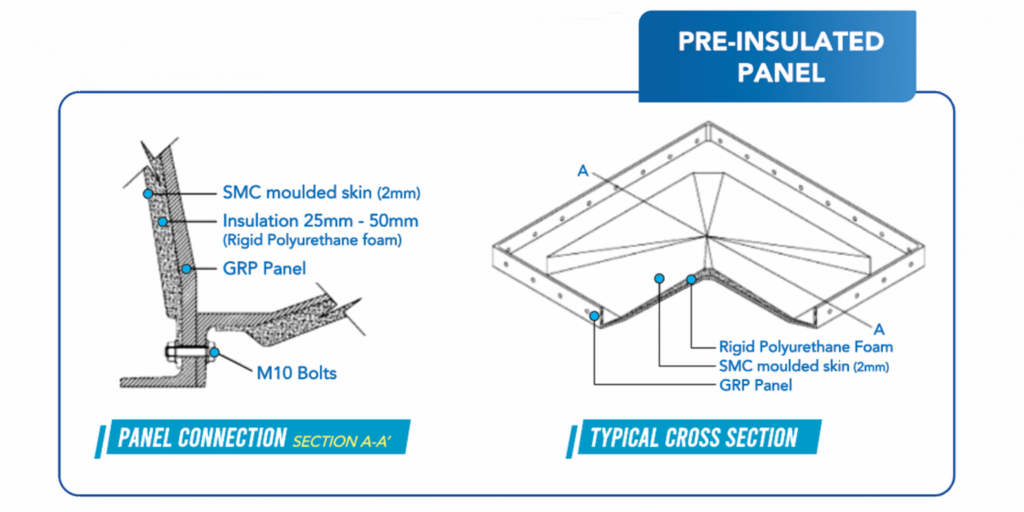

PRE-Insulated Panel

By encapsulating a 25mm ~ 50mm layer of rigid polyurethane foam, POTAGLAS pre-insulated panel could maintain the desired water temperature stored inside the tank under extreme temperature condition. POTAGLAS pre-insulated panel could be selected for water storage where there is a need to stabilize the temperature against extreme heat or freezing conditions so to prevent dew formation.

*Flange height (FH) varies according panel series

*Standard colour: gray

Performance of Panel

CHARACTERISTICS | POTAGLAS GRP TANK PANEL PERFORMANCE | ACCEPTANCE CRITERIA (SS 245:2014 SPECIFICATION) |

Tensile Strength (MN/m²) | > 103 | >70 (min) |

Bending Strength (MN/m²) | > 171 | > 100 (min) |

Elastic Modulus in Bend (MN/m²) | > 12260 | > 6000 (min) |

Glass Content (%) | > 40 | > 25 (min) |

Barcol Hardness | 57 | >30 (min) |

Water Absorption (%) | 0.1 | 0.5 (max) |

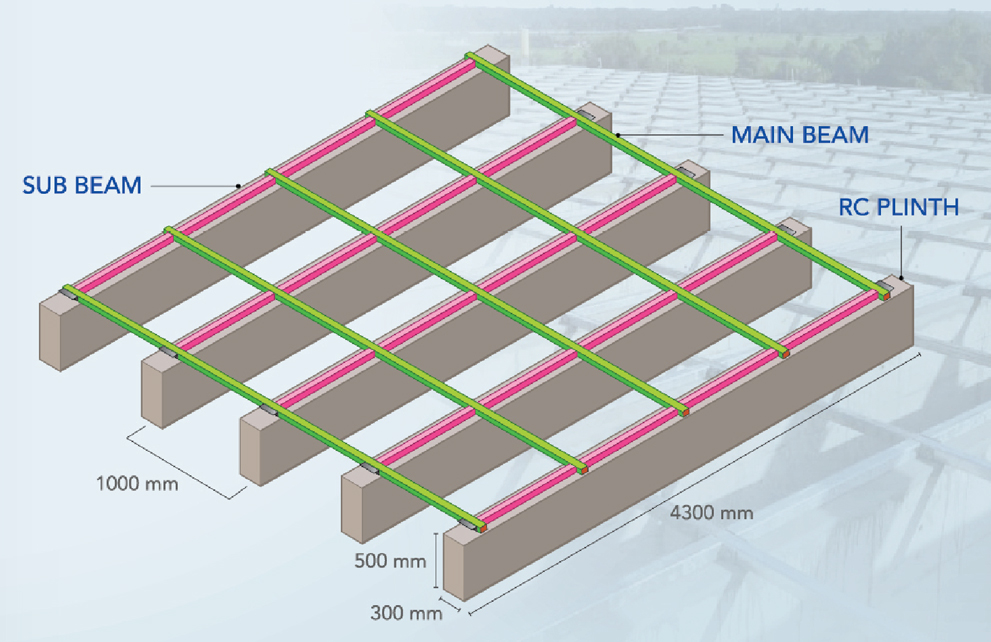

Skid Base Specifications

TANK HEIGHT | MAIN BEAM | SUB BEAM | CONCRETE PLINTH DISTANCE |

1.5m | HDG Hollow Section 50mm x 50mm x 3mm | HDG Hollow Section 50mm x 50mm x 3mm | 1000mm c/c *c/c = centre to centre |

2.0m | HDG Hollow Section 50mm x 50mm x 3mm | HDG Hollow Section 50mm x 50mm x 3mm | 1000mm c/c *c/c = centre to centre |

2.5m | HDG Hollow Section 50mm x 50mm x 3mm | HDG Hollow Section 50mm x 50mm x 3mm | 1000mm c/c *c/c = centre to centre |

3.0m | HDG Hollow Section 50mm x 50mm x 3mm | HDG Hollow Section 50mm x 50mm x 3mm | 1000mm c/c *c/c = centre to centre |

3.5m | Hollow Section 50mm x 50mm x 4.5mm | Hollow Section 50mm x 50mm x 4.5mm | 1000mm c/c *c/c = centre to centre |

4.0m | Hollow Section 50mm x 50mm x 4.5mm | Hollow Section 50mm x 50mm x 4.5mm | 1000mm c/c *c/c = centre to centre |

*Potaglas reserves the right to provide alternate skid base designs depending on the site condition and material availability.

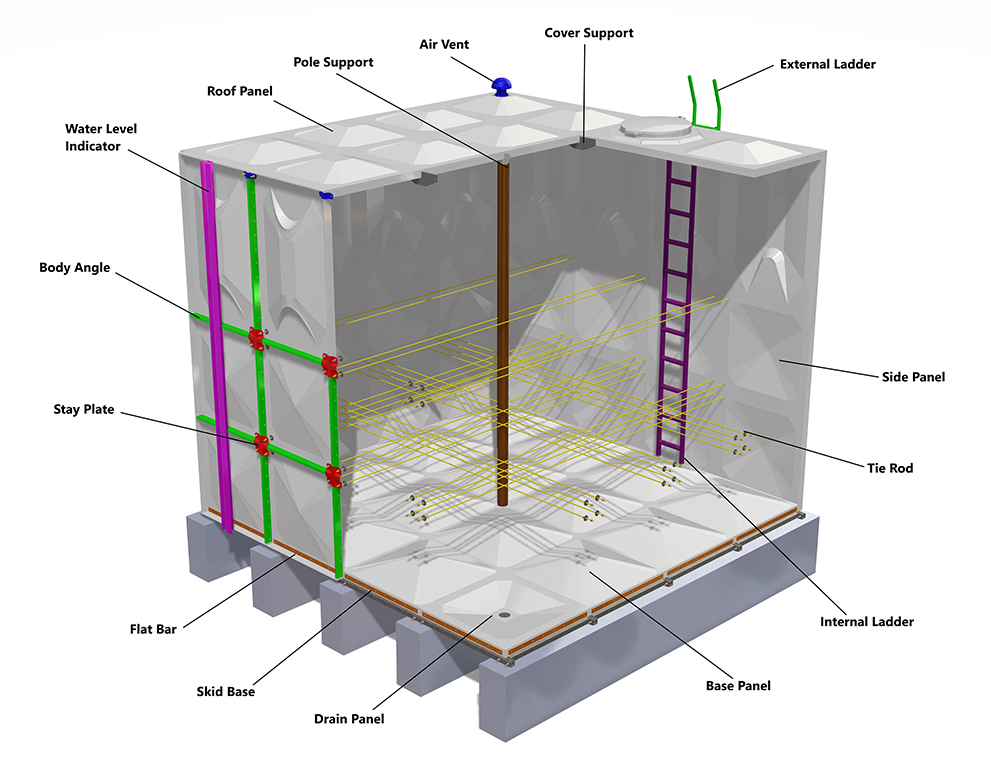

Internal Tie-Rod Design

MAIN COMPONENTS | EXTERNAL STRUCTURAL SUPPORT | INTERNAL STRUCTURAL SUPPORT | TANK ACCESSORIES |

Top Panel | Body Angle | Pole | Access Manhole |

Side Panel | Corner Angle | Pole Support | Air Vent |

Bottom Panel | – | Tie Rod | Water Level Indicator |

Drain/Pit Panel | Flat Bar | Roof Support | Internal Ladder |

Stay Plate | In Corner Bracket | External Ladder |

Potaglas GRP sectional water tank is constructed with bottom, side and top panels, completes with external and internal structural reinforcement and necessary tank accessories to facilitate water storage.

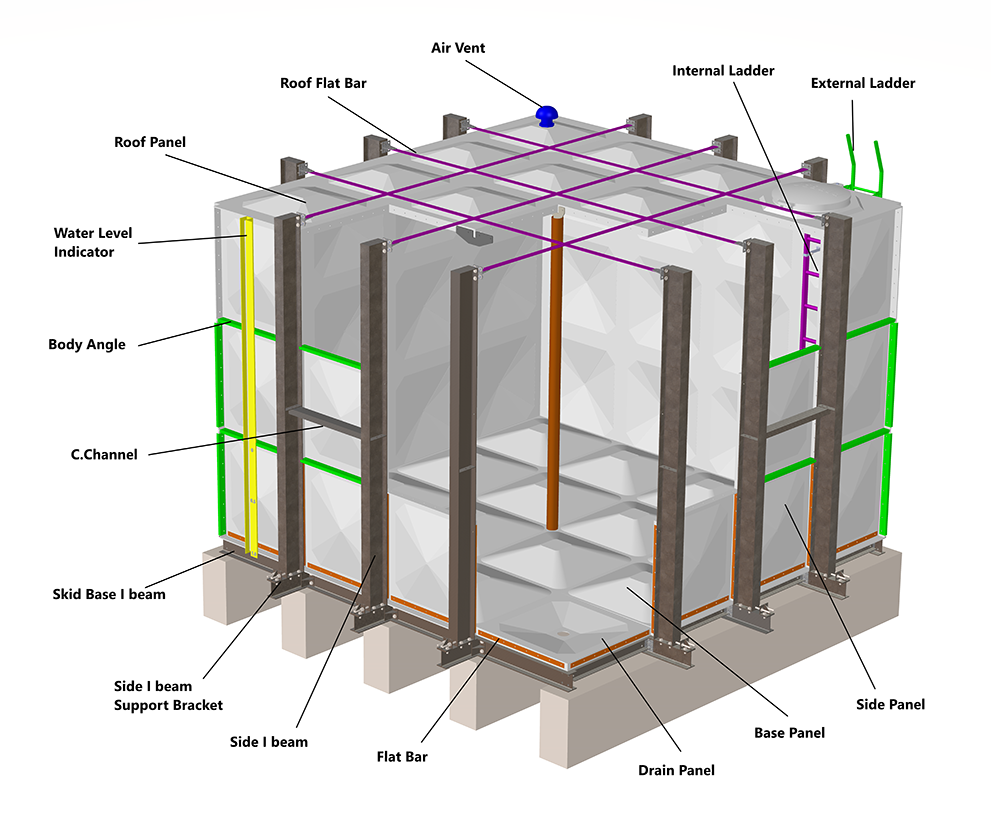

External Braced Design

MAIN COMPONENTS | EXTERNAL STRUCTURAL SUPPORT | INTERNAL STRUCTURAL SUPPORT | TANK ACCESSORIES |

Top Panel | Flat Bar | Pole | Access Manhole |

Side Panel | Body Angle | Pole Support | Internal Ladder |

Bottom Panel | – | Roof Support | External Ladder |

Drain/Pit Panel | C-Channel | In Corner Bracket | Air Vent |

Vertical I Beam | Tube Level Indicator | ||

Roof Flat Bar | |||

Side I Beam Support Bracket | |||

External Bracing Support |